2025 I 01 I 20

The recent completion of studies on our developing surface treatment technology supports our assumption that high-energy-density processes can be effectively applied and automated under industrial conditions.

During our research, we examined the effects of different atmospheres used for surface treatment and began developing the integration of the technology into equipment

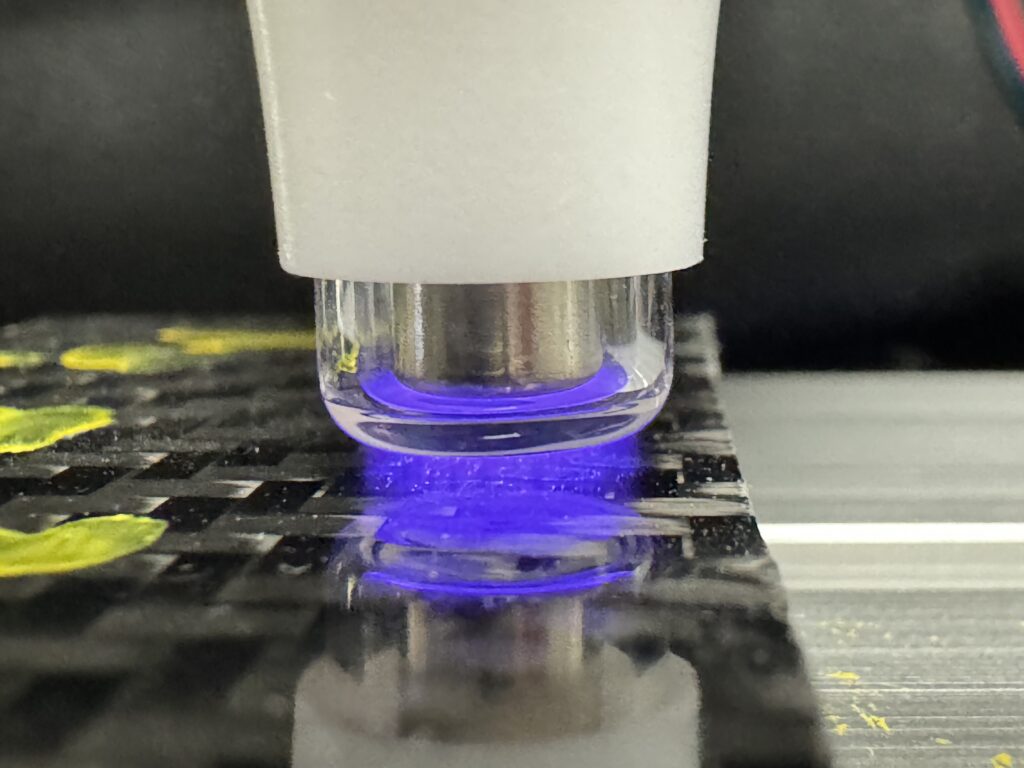

We analyzed the efficiency of the surface modification processes using various measurement methods. In these studies, we applied high-energy treatments that chemically modified the atoms in the top layers of the materials, thereby improving bonding efficiency. With the application of optimal settings, the adhesion of the surfaces significantly improved. The studies confirmed that laser treatment is excellently suited for the development of industrial adhesive bonding technologies.

2024 I 02 I 05

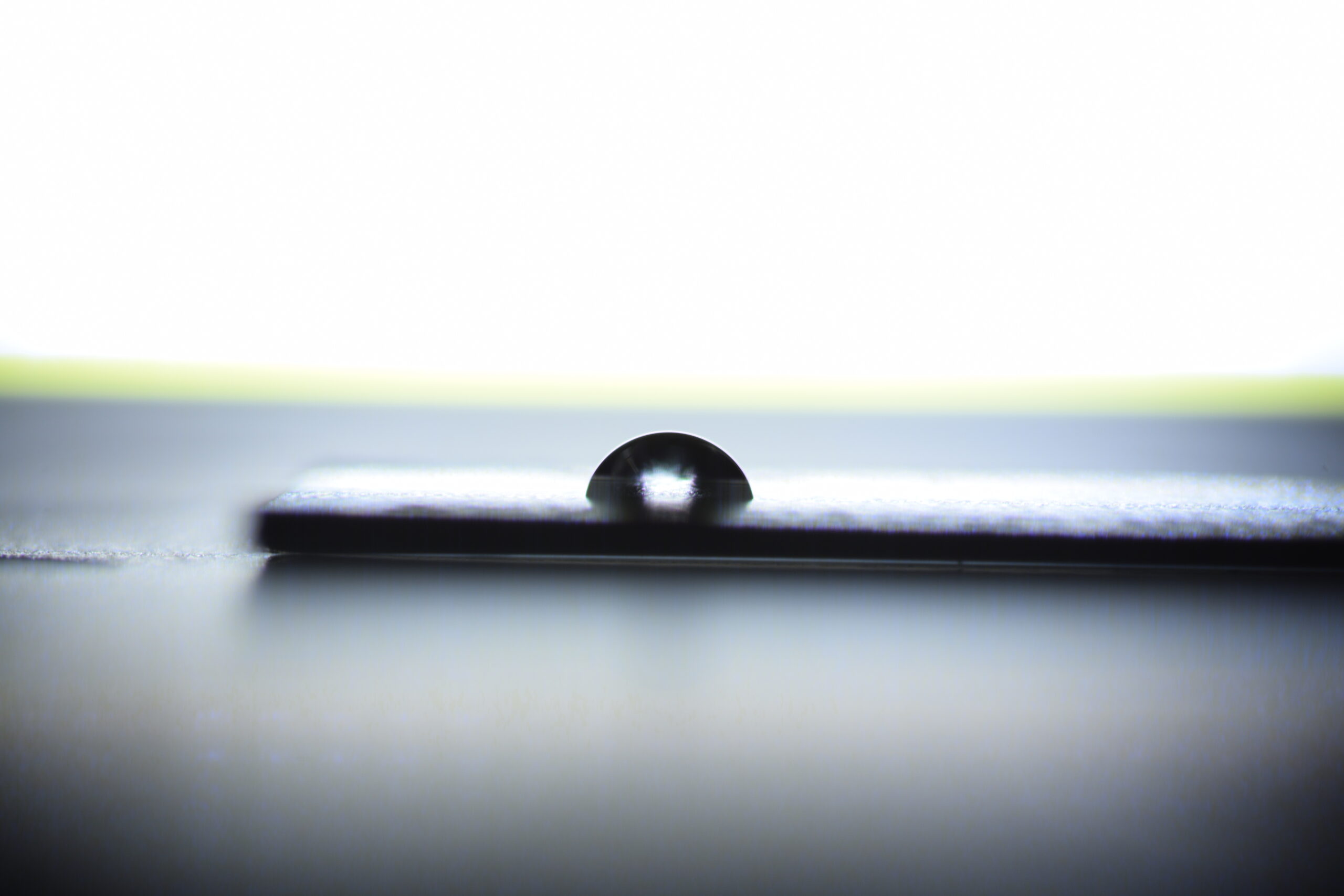

We have successfully modified the surfaces of several new types of materials and material mixtures using a high-energy-density radiation source, a result achieved due to the influence of literature results and our preliminary research findings. This complex surface treatment process has altered the presence of chemical groups on the surface, which is crucial in bonding technology. We have begun to develop a procedure suitable for the examination and development of various materials. The effects of the surface treatment were studied using the sessile drop method, thereby making the changes at the material interfaces traceable. By increasing surface activity, our experiments have fostered better interaction and stronger bonding. Our goal is to modify the surfaces of modern materials in a favorable direction according to engineering standards, using processes that alter this thin boundary layer. Modern, high-energy-density point-source and localized surface treatment techniques have proven effective in improving surface properties.

2023|02|14

EVOCON Trading and Service Limited Liability Company recently started implementing a research and development project with the title "Development of surface activation equipment for the optimization of adhesive joints", ID number 1.1.4-GYORSÍTÓSÁV-2022-00065.

The development processes and research in which environmental protection is a main aspect, of course, in addition to economy, are part of our everyday life. This trend is present in most industries, as environmentally friendly and energy-efficient solutions are given a particularly important role in all areas. Currently, one of the most dynamically developing branches of research and development is the use of new types of materials, the complex form of use of new materials and the related hybrid material pairings. However, the appearance of these materials also means new bonding technology challenges, since the bonding between the parts has at least as important a role as the properties of the material used. In line with today's industrial needs, the aim of the project is to develop a surface treatment, surface activation technology and related equipment that has been experimentally verified in advance and works under laboratory conditions, which is a very useful tool for industry players in terms of improving the strength of bonding technologies, as even complex bonding technology tasks can be solved with gluing which are unimaginable with other methods, in addition to the fact that there is no heat load on the materials to be connected, and it also has a good vibration dampening, insulating and noise reducing effect.

The physical implementation of the project began on January 1, 2023, and the planned completion date is December 31, 2025.

The project with a total cost of HUF 315,700,000 will be implemented by the minister responsible for the coordination of science policy, through the National Research, Development and Innovation Office, as the managing body, under the call for tenders announced with the code number 2021-1.1.4-GYORSÍTÓSÁV, with a total cost of HUF 255.320.000 from the NRDI Fund. , won a grant without repayment obligation. The intensity of the support is 80.87% of the eligible total cost of the project.

The ID number of the project: 1.1.4-GYORSÍTÓSÁV-2022-00065

Accountable gross total cost of the project: HUF 315.7 million

The amount of the non-refundable subsidy is HUF 255.32 million

Amount of support: 80.87% of the total eligible cost of the project

Place of implementation: 6500 Baja, Neumann János St. 1.A

The planned date of the completion of the project: 31.12.2025.

Contact person

EVOCON Ltd.

Annemária Hárschné Végh General Manager

tel: +36 304 955 534

e-mail: evoconkft@gmail.com

https://www.evocon.hu

2022|11|04

Az tudománypolitika koordinációjáért felelős miniszter által a Nemzeti Kutatási, Fejlesztési és Innovációs Hivatal, mint kezelő szerv útján, 2021-1.1.4-GYORSÍTÓSÁV kódszámmal meghirdetett pályázati kiírás keretében cégünk „Felületaktiváló berendezés fejlesztése ragasztási kötések optimalizálásához” címmel 2022. áprilisában támogatási kérelmet nyújtott be. A Támogatási Kérelem elbírálását követően a tudománypolitika koordinációjáért felelős miniszter (a 2022. 10. 19. napján kelt döntés értelmében) a Támogatási Kérelemben részletezett projektjavaslatot a Nemzeti Kutatási, Fejlesztési és Innovációs Alapból támogatásra érdemesnek minősítette.

The (planned) start date of the physical implementation of the project is 01.12.2022, for which the NRDI Fund provides a total of HUF 255.320.000 non-refundable support.